The most complete swimming pool bathtub manufacturer

Best Scum Absorber

Buoy Bed Pool Floats

Best quality beach bag wholesaler

BEST SELLING PRODUCTS

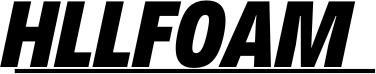

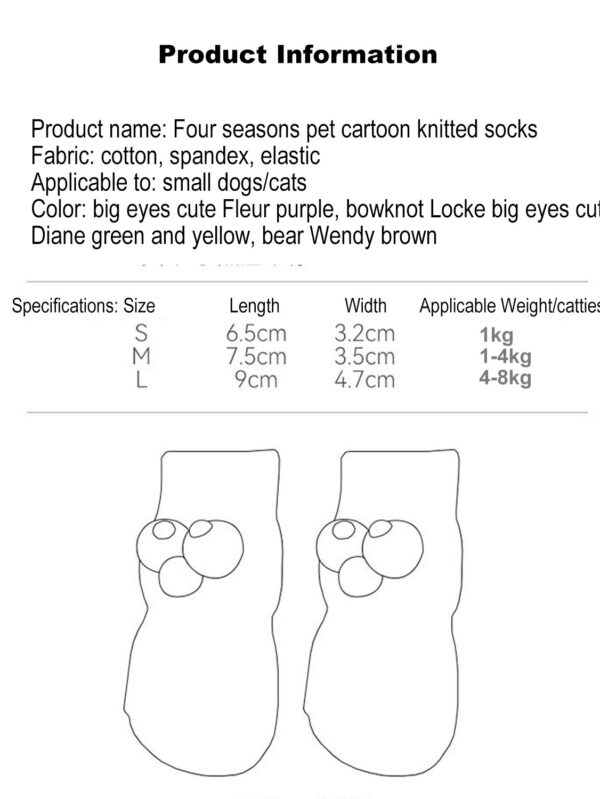

Cute socks for dogs and cats in all seasons

Floating beverage holder tea table tray

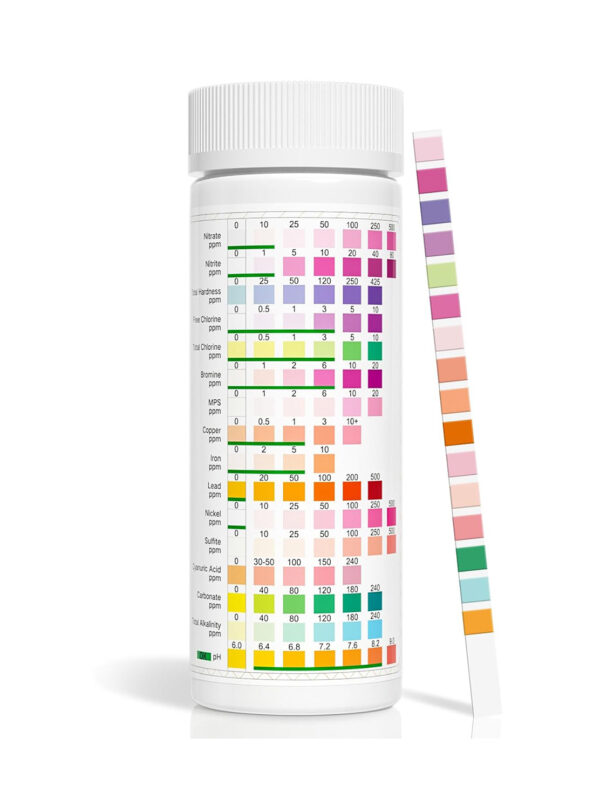

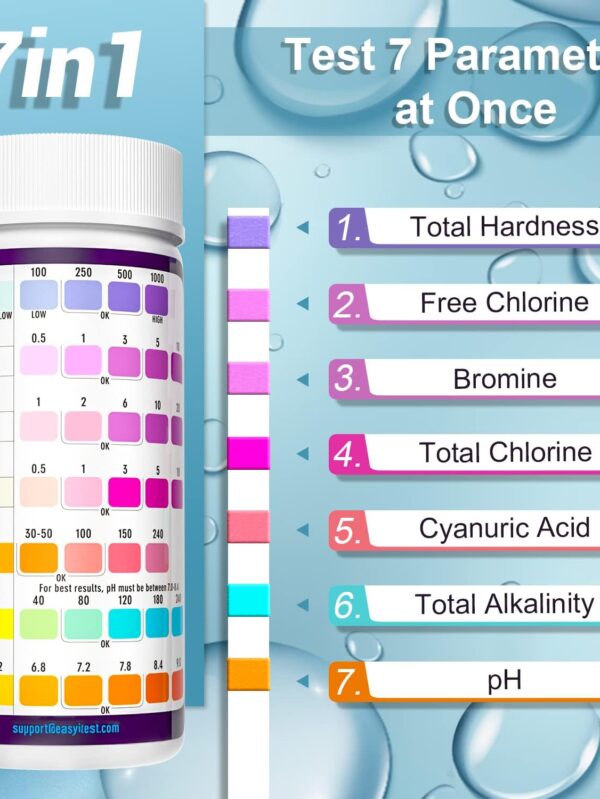

Water Chemistry Test Papers for Hot Tubs and Spas

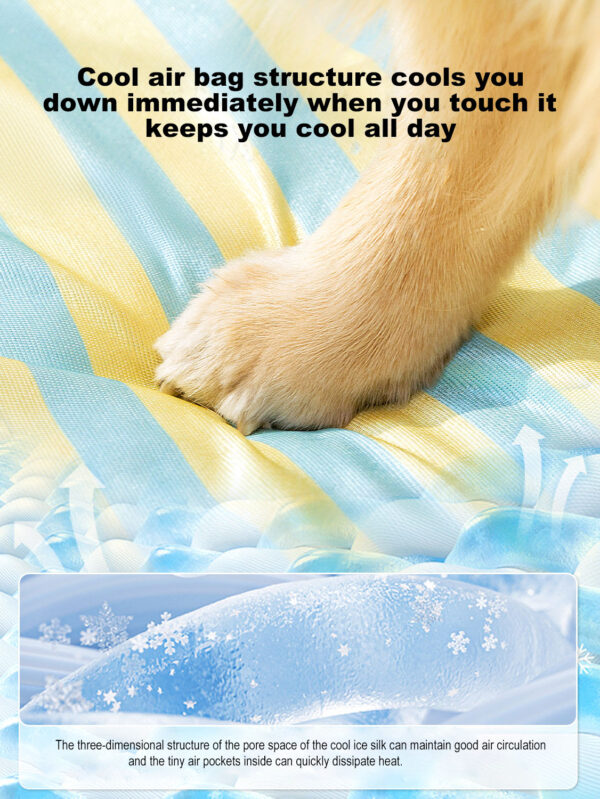

Dog cartoon striped ice silk mat cat cooling mat

Aquarium Sponge Filter Pad, Bio Filter Media Foam Sponges

Hot Tub Perfect Floating Scum Collector

The most professional eva injection molding factory

Beach Bag Tote Bag

Beach Bag

The oversized EVA tote is designed with your outdoor travel in mind, so we designed large, medium and small beach bags that are waterproof, sand-proof and washable, there is always a beach bag that fits you. . The beach tote is made of high-quality EVA material, which is sturdy, durable, quick-drying, non-slip textured bottom, soft shoulder straps, fashionable and cute color schemes, simplify your lifestyle.

Best Gift

How happy your girlfriend, mom will be when they receive the waterproof beach tote bag, they will love this stylish, cute and durable washable boat tote bag,If you have any questions, you can always contact us, we will solve your problems in a timely manner, you can rest assured to buy bag with holes beach.

bag on beach

You can use beach tote bag in any occasion, rubber beach bag for women is suitable for daily leisure bags, shopping bags, swimming bags, beach bags, fitness bags, yoga bags, picnic baskets, vegetable baskets, sports bags, etc. outdoor waterproof beach bag is fashionable and convenient.

Our Team

We are proficient in all kinds of EVA injection molding products and have our own factory. While completing your products with high quality, we will also help you save more profits. Our service is 7-24h to bring you a better experience.

WE ARE ON INSTAGRAM

FAST & FREE SHIPPING OVER $200

Deliver your products to you quickly

EXPERT CUSTOMER SERVICE

8:00 - 20:00, 7 days/week

FREE GIFT WRAPPING

With your custom message